Frequently Asked Questions

PT. Surya Cakra Mandiri, we aim to provide clear and practical information for engineers, contractors, and project owners looking for reliable cable management systems.

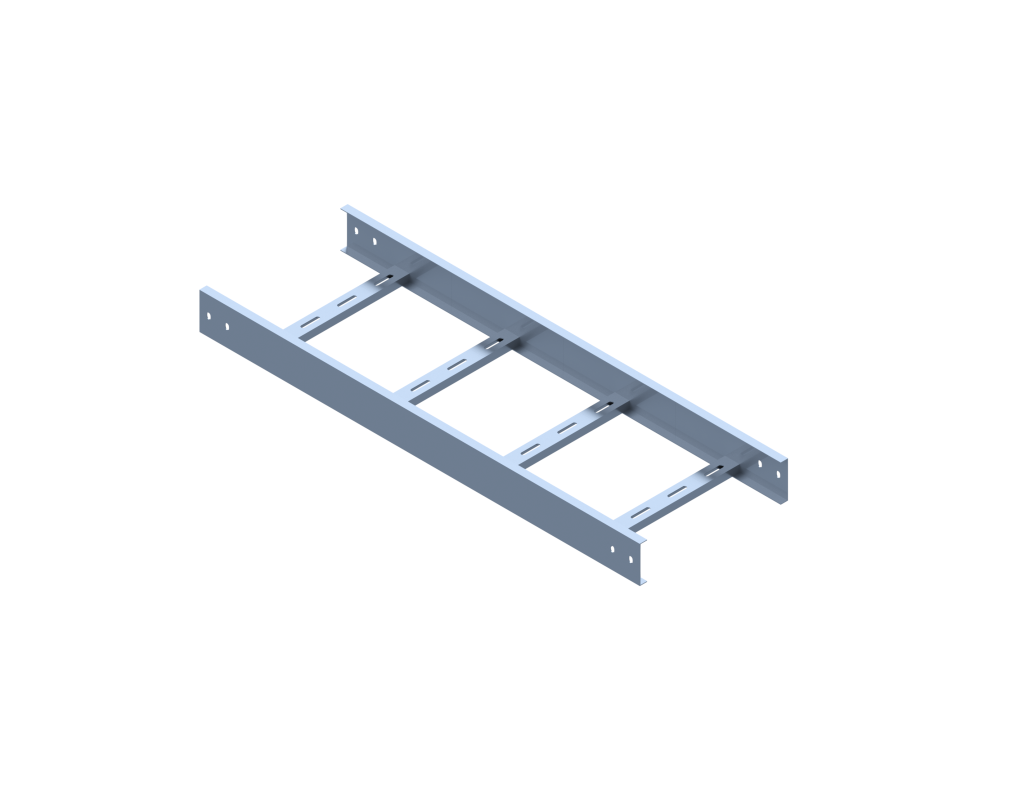

Cable Ladders have an open rung design — ideal for heavy cables and high ventilation.

Cable Trays are solid or perforated, suitable for lighter cables or indoor use.

Use Hot Dip Galvanized Steel for general industrial use.

Stainless Steel (SS304 / SS316) for corrosive or outdoor environments.

FRP/GRP for chemical plants or marine applications.

Yes. We offer custom widths, lengths, rung spacing, and coatings based on your project requirements.

All products are manufactured under ISO 9001, ISO 14001, and OHSAS 18001 to ensure consistent quality and safety.

Yes, SCM-B Tray provides nationwide delivery across Indonesia with reliable logistics support.